Tel:400-0058-999

Add:No. 2200, Section 3, South Street,Wafangdian City, Liaoning Province, China

Tel:0411-85647733

Fax:0411-85647666

Website:www.xzjcmc.com

HOW TO USE ULTRASOUND TO UPGRADE LUBRICATION PRACTICES

Release Time:21 Feb,2017

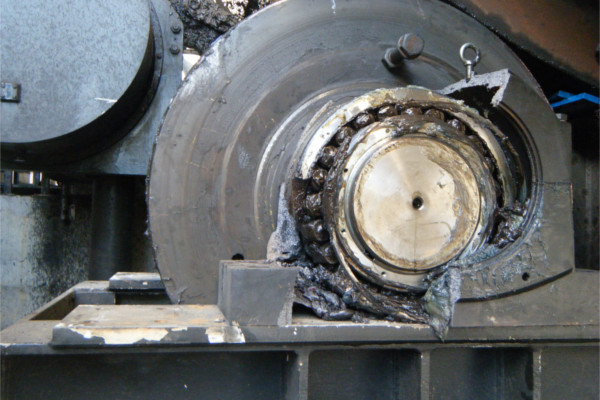

Avoid these 3 mistakes when lubricating bearings Friction is all around us. Without it we would find it very difficult to run, walk, or even stand on our own two feet. We need friction to drive our cars and fly our airplanes; and we need friction for our motors to drive pumps. But when it comes to our plant machinery, friction is both friend and foe. If part of your job is greasing plant machinery then you know well the battle against frictional forces that threatens the useful life of rolling element bearings. Lubrication of rolling element bearings is one of the most misunderstood and abused tasks in industry. Can it be true that 40% of bearings never live to their engineered life cycle and that bad lubrication practices are the leading cause of this mortality? Bearings depend on grease to reduce friction levels. By avoiding three common mistakes when greasing bearings you can predict the right time to grease, know how much grease to apply, and be confident in the bearing’s overall health. Mistake n°1 – Lubricating based on TIME instead of CONDITION

Lubricating a bearing once per week or once per month may seem like a sensible thing to do. After all, performing scheduled maintenance at regular periods is an age-old concept.

Bearings need grease for one reason only; to reduce friction. As long as the lubricant is performing that service well, there should be no need to change it, or add more. Yet we frequently do, with catastrophic results.

Lubricating a bearing just because your calendar told you “time is up!” is the first mistake. Monitor, measure and trend friction levels with ultrasound to know when it is the right time to grease.

Mistake n°2 – Over and under lubrication

The second mistake we must avoid is adding too much, or not enough grease. Too much grease builds pressure, pushing the rolling elements through the fluid film and against the outer race. The bearing now has to work much harder to push the rolling elements through a mud bog of grease.

The increased friction and pressure from too much grease raises the temperature inside the bearing. Excess heat could decrease the effectiveness of the lubricant causing the oil to separate from the thickener. Not adding enough grease has the same life-shortening effect.

How do we know when just the right amount of grease has been added? By monitoring the friction level with ultrasound as new grease is applied… slowly, one shot at a time. Listen to the bearing and measure the drop in friction as the grease flows in to the bearing. As the decibel level approaches a minimum value and stabilizes pay close attention. Add single shots. Should the decibel level begin to increase slightly, stop! The job is done.

Mistake n°3 – Using a “Listen-Only” ultrasound instrument

Like any job there is a right way and a wrong way to do things. Simply listening to a bearing with an ultrasound device that gives no measurement feedback is a recipe for disaster. The audible feedback alone is too subjective to draw any comparative conclusions. No two people hear the same and there is no way to remember what the bearing sounded like a month ago.

The third mistake is depending solely on subjective ultrasound noise when precise quantifiable data is available. Therefore always use an ultrasound instrument with digital decibel metering. Better still, use a device that provides multiple condition indicators. Max RMS and Peak dB measurements indicate alarm levels and greasing intervals while Ultrasonic Crest Factor provides insight about the bearing condition in relation to its lubricant. Crest Factor helps us differentiate between bearings that need grease and bearings that need to be replaced.

Before greasing

Mistake n°1 – Lubricating based on TIME instead of CONDITION

Lubricating a bearing once per week or once per month may seem like a sensible thing to do. After all, performing scheduled maintenance at regular periods is an age-old concept.

Bearings need grease for one reason only; to reduce friction. As long as the lubricant is performing that service well, there should be no need to change it, or add more. Yet we frequently do, with catastrophic results.

Lubricating a bearing just because your calendar told you “time is up!” is the first mistake. Monitor, measure and trend friction levels with ultrasound to know when it is the right time to grease.

Mistake n°2 – Over and under lubrication

The second mistake we must avoid is adding too much, or not enough grease. Too much grease builds pressure, pushing the rolling elements through the fluid film and against the outer race. The bearing now has to work much harder to push the rolling elements through a mud bog of grease.

The increased friction and pressure from too much grease raises the temperature inside the bearing. Excess heat could decrease the effectiveness of the lubricant causing the oil to separate from the thickener. Not adding enough grease has the same life-shortening effect.

How do we know when just the right amount of grease has been added? By monitoring the friction level with ultrasound as new grease is applied… slowly, one shot at a time. Listen to the bearing and measure the drop in friction as the grease flows in to the bearing. As the decibel level approaches a minimum value and stabilizes pay close attention. Add single shots. Should the decibel level begin to increase slightly, stop! The job is done.

Mistake n°3 – Using a “Listen-Only” ultrasound instrument

Like any job there is a right way and a wrong way to do things. Simply listening to a bearing with an ultrasound device that gives no measurement feedback is a recipe for disaster. The audible feedback alone is too subjective to draw any comparative conclusions. No two people hear the same and there is no way to remember what the bearing sounded like a month ago.

The third mistake is depending solely on subjective ultrasound noise when precise quantifiable data is available. Therefore always use an ultrasound instrument with digital decibel metering. Better still, use a device that provides multiple condition indicators. Max RMS and Peak dB measurements indicate alarm levels and greasing intervals while Ultrasonic Crest Factor provides insight about the bearing condition in relation to its lubricant. Crest Factor helps us differentiate between bearings that need grease and bearings that need to be replaced.

Before greasing

After greasing

After greasing

When the ideal lubrication level is reached, the dB microvolts value returns to its normal level. This is perfectly audible in the headphones, in the reproduction of the dynamic signal and visible on the screen of the SDT device.

Clear benefits of avoiding the three mistakes

Ultrasound assisted lubrication of plant assets offers significant benefits that calendar-based lubrication cannot. Lubrication serves a primary purpose, which is to create a thin layer of lubricant between rolling and sliding elements that reduces friction. So it makes sense that the best way to determine the lubrication requirement of a machine is to monitor friction levels; not time in service.

Optimizing lubrication of plant machinery with ultrasound will result in a significant reduction in grease consumption. Having an ultrasound program in place will help create a better culture involving cleaner storage practices, sampling, and avoiding mixing greases.

When the ideal lubrication level is reached, the dB microvolts value returns to its normal level. This is perfectly audible in the headphones, in the reproduction of the dynamic signal and visible on the screen of the SDT device.

Clear benefits of avoiding the three mistakes

Ultrasound assisted lubrication of plant assets offers significant benefits that calendar-based lubrication cannot. Lubrication serves a primary purpose, which is to create a thin layer of lubricant between rolling and sliding elements that reduces friction. So it makes sense that the best way to determine the lubrication requirement of a machine is to monitor friction levels; not time in service.

Optimizing lubrication of plant machinery with ultrasound will result in a significant reduction in grease consumption. Having an ultrasound program in place will help create a better culture involving cleaner storage practices, sampling, and avoiding mixing greases.

Machines that are properly lubricated require less energy to run. Imagine that reducing the amount of money spent on grease will actually lead to lower energy bills. Machines that consume less electricity run cooler and machines that run cooler have longer life cycles.

Ok, the real reason to optimize bearing lubrication is to extend the life of bearings by making sure they have the right amount of grease, but not too much. When everything is running according to plan lube-techs will spend less time greasing bearings that do not need it. So when counting up the benefits of your ultrasound program does not forget to add “decreased labor” to the long list.

Finally, by monitoring the condition of your machinery’s lubrication, you are at the same time collecting valuable condition data about the machine itself. Dynamic and static ultrasound data coupled with condition indicators such as Overall RMS, Max RMS, Peak, and Crest Factor are all indicators of bearing health. A practice that does not use this SDT combination is not a real solution when lubricating bearings. Who knew so much good could come from such a simple shift from calendar to condition based maintenance?Now You Know.

Machines that are properly lubricated require less energy to run. Imagine that reducing the amount of money spent on grease will actually lead to lower energy bills. Machines that consume less electricity run cooler and machines that run cooler have longer life cycles.

Ok, the real reason to optimize bearing lubrication is to extend the life of bearings by making sure they have the right amount of grease, but not too much. When everything is running according to plan lube-techs will spend less time greasing bearings that do not need it. So when counting up the benefits of your ultrasound program does not forget to add “decreased labor” to the long list.

Finally, by monitoring the condition of your machinery’s lubrication, you are at the same time collecting valuable condition data about the machine itself. Dynamic and static ultrasound data coupled with condition indicators such as Overall RMS, Max RMS, Peak, and Crest Factor are all indicators of bearing health. A practice that does not use this SDT combination is not a real solution when lubricating bearings. Who knew so much good could come from such a simple shift from calendar to condition based maintenance?Now You Know.

Mobile Website

Wechat Platform

Wafangdian GuangyangBearing Group Co., Ltd.

Equipment & Capability

Copyright@2017Wafangdian Guangyang Bearing Group Co., Ltd.